AUTOSCHEDULER.AI FEATURED IN Workplace Material Handling & Safety

WMS Accelerators Bring Warehouses Into the 21st Century

Advanced technology simplifies planning and scheduling.

By Keith Moore – Posted November 1, 2023

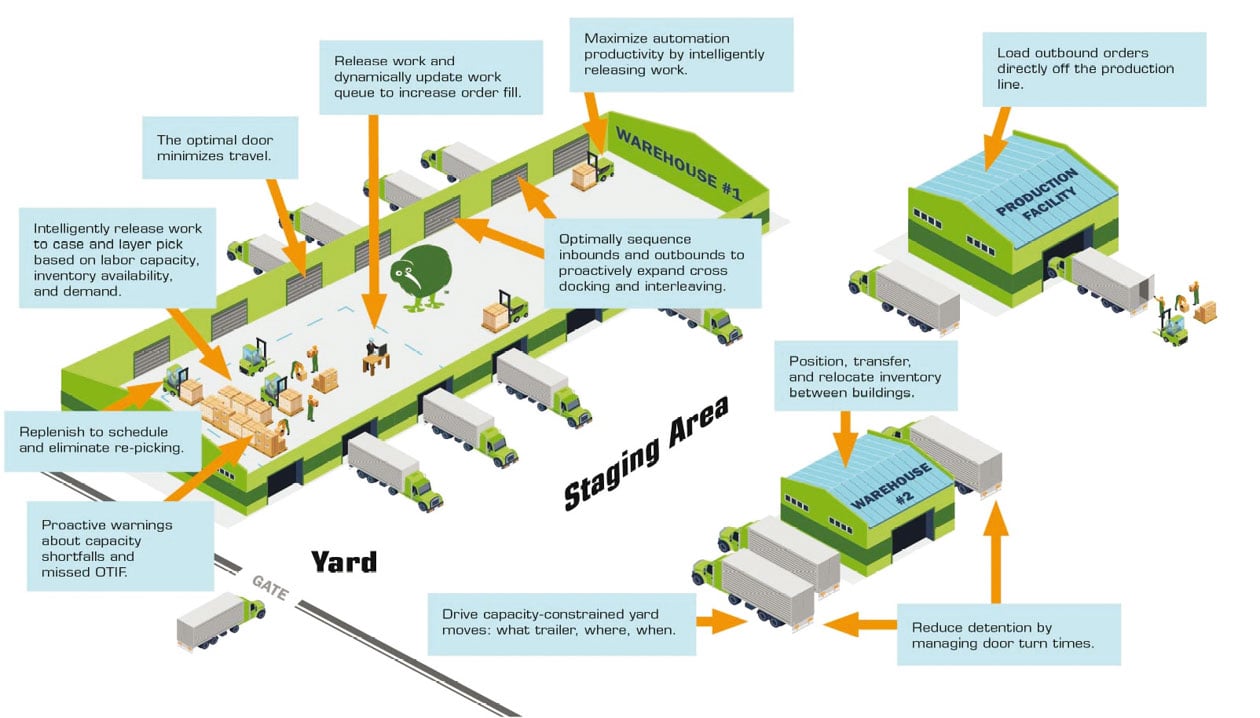

At a high level, managing a warehouse looks simple – inventory flows in and out, and you store a few things in the middle. In practice, managing a warehouse is akin to conducting a symphony. Each section, from inventory to labor, must play in harmony to produce the desired outcome: timely and accurate deliveries to every customer exactly when they need the product. To maximize service levels and reduce costs, companies often introduce automated warehouse technologies to manage some of the complexity in their warehouse. While these new technologies can often provide significant benefits in their functions, they can also create additional complexity due to the interchanges between automated and non-automated process flows.

The global warehouse automation market is estimated to grow at a compound annual growth rate (CAGR) of 15%, reaching a value of $41 billion by 2027, according to Logisticsiq, which creates a chart of 10 technologies and vendors that offer these technologies. Per Logisticsiq’s research, the top warehouse technologies include:

- Autonomous Guided Vehicles (AGV) / Autonomous Mobile Robots (AMR)

- Automated Storage Retrieval Systems (ASRS)

- Conveyors

- Sortation Devices

- Order Picking Technologies

- Automatic ID and Data Capture

- Palletizing & Depalletizing

- Gantry Robots

- Overhead Systems

- Warehouse Management Systems (WMS) / Warehouse Execution Systems (WES)/ Warehouse Control Systems (WCS)

Warehouses must adopt the combination of hardware and software technologies like those listed above to deal with supply chain complexities such as fluctuating consumer demand, fuel price increases, parts shortages and labor shortages. Addressing these challenges and meeting demand often requires sophisticated planning and scheduling solutions to integrate all the different technologies. Many companies think they can do all this using a warehouse management system (WMS).